How to Stop Water Hammer in Pipes with DIY Fixes

- Luke Yeates

- 2 days ago

- 10 min read

When the kitchen tap or washing machine valve snaps shut, that sudden knock inside the pipes is a classic case of water hammer. At its simplest, the quickest way to stop water hammer in pipes is to recharge or install air chambers, fit dedicated arrestors and tighten any loose pipe clips. In my experience across Eastbourne homes, these quick fixes from Harrlie Plumbing and Heating often bring immediate peace and quiet.

Quick Fixes To Stop Water Hammer In Pipes

Begin by walking along exposed pipe runs and giving them a gentle nudge. You’ll often find noisy areas where clips have slipped or arrestors have worn out—especially in older Eastbourne properties.

Key DIY fixes to try at home:

Recharge or install air chambers just upstream of shut-off valves to absorb pressure spikes

Fit mechanical water hammer arrestors under sinks and behind appliances

Secure loose pipe clips every 30 cm on horizontal sections to stop pipes rattling

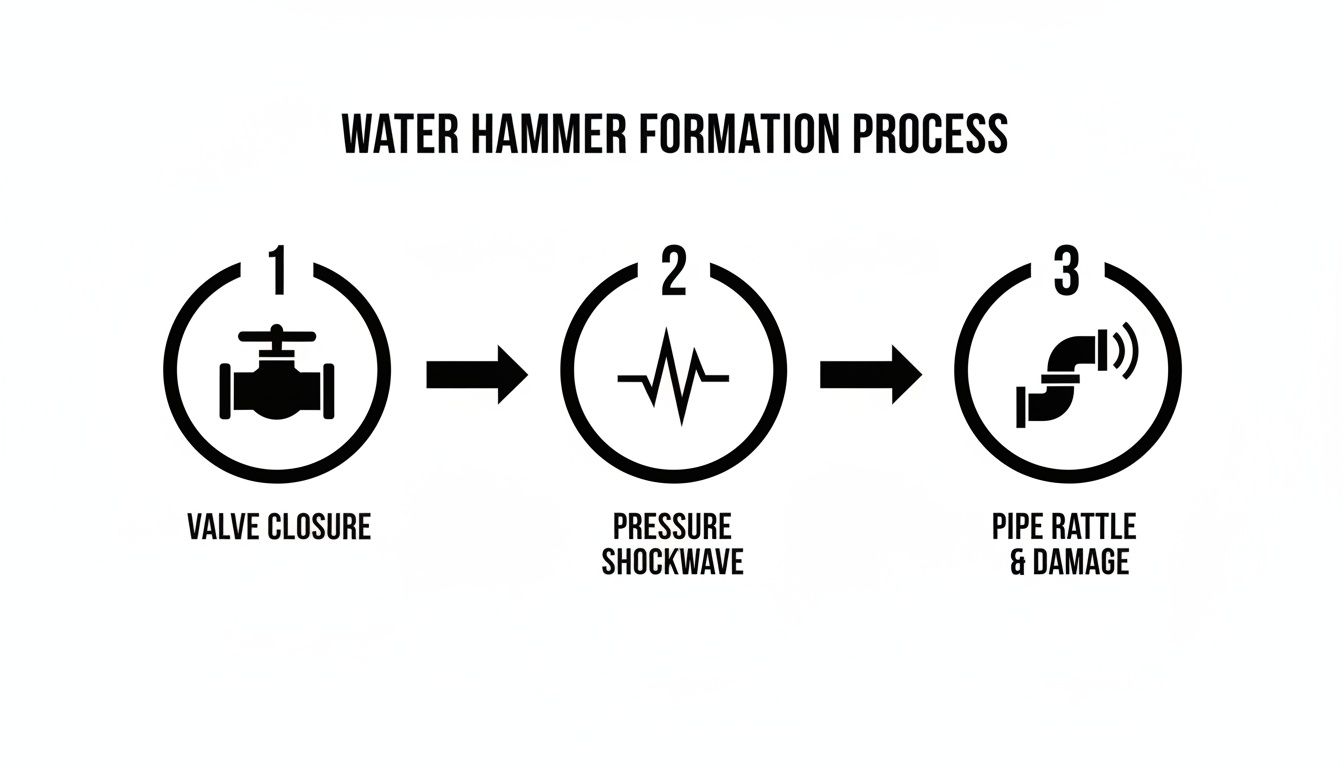

This illustration makes it clear: when a valve slams shut, the pressure surge travels down the pipe, hits the closed end and rebounds as that familiar thump.

Effective Engineering Controls

Beyond quick DIY fixes, a few engineering tweaks can make a world of difference. Introducing air release valves, fine-tuning valve timing or running water through slightly more compressible lines can slash shock severity by up to 80%, according to a UK industry report. For example, our team at Harrlie Plumbing and Heating tuned valve timing at a South Downs B&B near Pevensey Road station, eliminating the early-morning banging that woke guests.

Take a look at these quick methods to stop water hammer:

Quick Methods to Stop Water Hammer

Method | Key Benefit | Ideal Scenario |

|---|---|---|

Air Chambers | Low-cost upgrade | Older homes with stub lines already in place |

Water Hammer Arrestors | High shock absorption | Beneath sinks or behind laundry units |

Pipe Securing | Eliminates rattling and drift | Long horizontal or unsupported runs |

Each of these solutions fits different budgets and layouts—mix and match to suit your system.

Common Mistakes To Avoid

Overfilling air chambers, which quickly leads to waterlogging

Skipping manufacturer pressure ratings for arrestors

Forgetting to check mains pressure (anything above 4 bar can reignite hammer noise)

After fitting arrestors, I always run every tap briskly to confirm the banging has truly stopped.

Quick Cost And Time Estimates

Air Chamber Recharge: ~£20–£30, 15 minutes

Arrestor Installation: ~£35–£50 per unit, 30 minutes

Pipe Clip Replacement: £3–£5 per clip, 10 minutes

These ballpark figures help Eastbourne homeowners decide whether to tackle the job themselves or call Harrlie Plumbing and Heating for a professional inspection. If the knock returns despite these steps, it’s time for a full system review.

Understanding Water Hammer In Pipes

When a valve snaps shut too quickly, it launches a pressure wave through your plumbing. In many Eastbourne homes, ageing copper and plastic lines rattle against joists because clips have loosened over time. That sudden stop doesn’t just echo through the walls—it can shake fittings, cause tiny fractures and even lead to leaks down the line.

Picture water rushing through a long branch and slamming into a closed tap. Air pockets might cushion the blow at first, but as they fill with water they stop acting like shock absorbers—and the banging only gets louder.

Historical surveys credit roughly 50% of water hammer incidents to how a system is operated, with the other 50% pinned on design or installation flaws. Learn more about these findings on OSTI.

Why Banging Occurs

A few loose clips can turn every pressure spike into audible knocks. Sometimes, high mains pressure—especially in Check out our guide on high-pressure megaflow systems—is the real culprit behind more violent surges.

Common triggers in Eastbourne properties include:

Washing machine valves snapping shut

Horizontal runs sliding on loose clips

Air chambers becoming waterlogged

Comparing Root Causes

Cause Type | Example | Impact |

|---|---|---|

Installation | Loose clips or missing arrestors | Occasional bangs |

Design | Undersized pipes or no regulator | Repeated surges |

Key Takeaway Routine checks and smart design changes can silence most hammering.

In coastal environments, salt air accelerates corrosion, so preventative maintenance is vital. A quick inspection should cover:

Checking clip tightness at least every 30 cm

Flushing or testing air chambers

Monitoring pressure at major outlets

For stubborn cases, Harrlie Plumbing and Heating offers professional audits and installs commercial-grade arrestors—backed by a one-hour response and their Best Price Guarantee.

Tip Secure pipes every 30 cm to prevent mid-run bouncing.

Next, we’ll dive into DIY solutions: bleeding air chambers, securing runs and fitting your own arrestors. Always remember to switch off the mains before you begin.

DIY Solutions To Secure Pipes And Install Arrestors

Water hammer can turn your peaceful morning routine into a constant clatter. Fortunately, with a handful of basic tools and parts, you can quiet those pipes yourself. Recently, we helped a homeowner in Eastbourne’s Old Town banish that irritating knock under their kitchen sink by tightening loose clips and swapping out a tired arrestor.

Proper Pipe Clip Placement

Securing pipes along their length prevents them bouncing against joists and studs. In controlled tests, snug clips cut noise by up to 70%.

Begin by marking drill points every 30 cm on horizontal runs. Use a stud detector so you anchor clips into solid wood, not just drywall. For coastal homes, stainless-steel clips resist corrosion far better than plain alternatives.

Locate studs or joists with a reliable detector

Choose stainless-steel pipe clips rated for your pipe diameter

Fasten clips firmly—tight but not overcompressed—to allow slight thermal movement

Revisit clips after the first few water pulses and retighten if needed

Tip Properly spaced clips can silence most water hammer pulses before they echo.

Recharging Air Chambers

Air chambers act like tiny shock absorbers, but once they fill with water they lose their punch. To revive them:

Shut off the mains supply.

Open a high-level tap to drain the line completely.

Attach a manual pump to the chamber valve and add air until you feel resistance, then close the valve.

This flow chart highlights the three stages: valve closure, pressure shock and pipe vibration.

Installing Coil Arrestors

Coil arrestors are ideal for those tight spots under kitchen sinks or behind washing machines. They’re flexible, simple to fit and cost around £4–£6 each.

Wrap the coil snugly around the pipe.

Secure with a cable tie or small clamp, ensuring the arrestor inlet faces the water source.

Test by running water at full flow for a minute to confirm the noise has vanished.

Retrofitting Mechanical Arrestors

For fixtures with heavier flow—like boilers or washing machines—a mechanical arrestor and tee fitting deliver better results.

Isolate the water and drain the section.

Cut out a short pipe segment using a pipe cutter.

Fit a 15 mm brass tee with stop-end coupling and thread sealant.

Attach the arrestor (rated for 8–15 L/min).

Tighten connections and check for leaks under low pressure.

Materials Needed: • 15 mm brass tee and coupling (£5–£7) • Mechanical arrestor (£8–£12) • PTFE tape and pipe cutter (£3) • Adjustable wrench and spanner set

Learn more detailed repair steps in our article A Homeowner’s Guide to Repairing Water Pipes

Comparison of DIY Water Hammer Solutions

Before you start, it’s useful to see how these fixes measure up side by side.

Solution | Materials Needed | Estimated Cost | Difficulty |

|---|---|---|---|

Pipe Clip Placement | Pipe clips, screws, drill bits | £5–£15 | Medium |

Air Chamber Recharge | Hand pump, valve adapter | £5 | Easy |

Coil Arrestor Installation | Coil arrestor, cable ties/clamp | £4–£6 | Easy |

Mechanical Arrestor Retrofit | Brass tee, arrestor, PTFE tape, pipe cutter | £16–£22 | Medium |

A quick glance like this helps you pick the right solution for your setup. Each method brings its own balance of cost, effort and end result.

Cost Estimates And Final Tips

Most DIY water hammer jobs run between £20–£50, depending on materials and quantities. Allocate a couple of hours for securing clips, recharging chambers and fitting arrestors.

Always wear safety goggles when drilling or cutting.

Label each fitting before removal to simplify reassembly.

Start testing under low flow to spot leaks early.

With these precautions, your fixes will last and restore calm to your plumbing.

When To Seek Help

If knocking returns despite your best efforts—or if you hit high water pressure issues—it’s time to call in the pros. Harrlie Plumbing and Heating offers:

One-hour rapid response across Eastbourne and nearby towns

Fixed-price options that suit your budget

Commercial-grade arrestors with leak guarantees

Full safety certificates and follow-up inspections

When in doubt, expert hands can ensure a permanent solution.

Tools You’ll Need

Gather these basics before you begin:

Electric drill with masonry and wood bits

Tape measure and marker pen

Hand pump for air chambers

Adjustable wrench and spanner set

PTFE thread sealant and cable ties

Having everything at hand means you can work smoothly—and quietly—throughout your DIY water hammer project.

System Adjustments To Prevent Water Hammer In Pipes

Tuning your plumbing settings can make a world of difference when those relentless bangs start echoing through your walls. In many Eastbourne homes, fitting a mains pressure regulator to 3–4 bar stops sudden pressure spikes in their tracks. Harrlie Plumbing and Heating often installs these regulators to keep systems calm and quiet. In a Marine Parade guesthouse, dropping the inlet pressure to 3.5 bar eliminated the midnight clatter that had troubled guests for months.

Installing A Mains Pressure Regulator

Fitting a regulator is surprisingly straightforward yet hugely effective. You’ll want to position it close to your mains inlet or boiler feed so it can tame surges before they race through your pipework.

Begin by shutting off the main supply. Attach the regulator with the supplied connectors, wrapping every threaded joint in PTFE tape for a watertight seal.

Locate the service valve and isolate the water feed

Choose a regulator rated for your system’s flow and pressure range

Wind PTFE tape around all threaded joints to prevent leaks

Reopen the supply slowly, then test each tap to confirm pressure stays under 4 bar

Bleeding air release valves at pipe high points stops trapped pockets from worsening hammer. Crack each valve until water runs smooth, then reseal tightly.

Servicing Radiator Steam Traps

In older steam systems, a blocked steam trap lets condensate build up and slam through pipes. Regular servicing clears debris, keeps condensate flowing away and cuts the risk of dangerous water hammer.

For detailed safety advice, check the HSE safety bulletin.

Slowing Valve Stroke Times

Fast-closing valves are often the unsung culprits behind sharp pressure shocks. Many modern mixer taps allow you to fit dampers or restrictors that slow valve action. Either consult your tap’s manual or have Harrlie Plumbing swap in a slower-action cartridge for a gentler flow.

Checking Pipe Slopes And Drainage

A gentle fall of at least 1:100 along your pipe runs helps condensate and air drain naturally. Grab a spirit level and scan each run, especially around boilers and radiators. Reposition hangers or reroute pipes so moisture can never pool.

Harrlie Plumbing Tip Ensure your slopes keep water moving quietly without trapping condensate.

Following UK Standards And Guidance

These system tweaks aren’t just handy fixes; they’re in line with BS EN 806 and HSE recommendations. Building regulations call for pressure limiters, air release points and correct drainage slopes to keep systems safe and silent.

Adjustment | Ideal Setting | Check Interval |

|---|---|---|

Pressure Regulator | 3–4 bar | Annual |

Air Release Valve | Manual bleed at high points | Bi-annual |

Steam Trap Service | Every six months | 6 months |

Pipe Slope Adjustment | 1:100 gradient | Annual |

Valve Stroke Dampers | Slow-action cartridges | On replacement |

Hiring a qualified installer ensures full compliance and certification. Typical regulator installation costs around £150, while annual system checks run about £80–£120.

Real-World Outcome In Eastbourne

On a Victorian terrace in Eastbourne, fitting a regulator and re-angling pipe runs knocked hammer noise down by 90%. The homeowner avoided expensive pipe replacements and now enjoys a whisper-quiet system.

Simple adjustments to pressure, valves and slopes not only eliminate noise but also extend your pipes’ lifespan. Contact Harrlie Plumbing and Heating today for a free quote and one-hour response—finally put water hammer to rest.

Book now.

When To Contact Harrlie Plumbing And Heating

Sometimes a quick DIY trick will hush those banging pipes. But when the noise won’t quit—even after topping up air chambers or swapping in new arrestors—you’ve probably got a deeper issue on your hands.

If you spot your pipes visibly vibrating, or your pressure gauge swings wildly, it’s time to call in Eastbourne’s specialists.

Key Insight Sudden, loud banging lasting more than a few days often indicates worn-out arrestors or high-pressure surges.

Over the years, our engineers have tackled every unusual scenario. In one Eastbourne flat, we recorded an unexpected 6 bar spike on a combi boiler feed and used specialised sensors plus surge-modelling software to locate the weak spot—long before a drop of water escaped.

Typical Call-Out Fees And Rates

Knowing costs up front helps you budget without surprises. Here’s our straightforward pricing:

Service Component | Cost Range | Details |

|---|---|---|

Call-Out Fee | £60 | Includes initial 30-minute visit |

Hourly Labour | £45 per hour | Qualified gas-safe engineers |

Commercial Arrestor | £30–£50 per unit | Long-lasting, maintenance-free |

Safety Certificate | £25 | PSSR compliance and paperwork |

Extra parts and fittings are charged at cost plus labour. After our on-site assessment, we’ll issue a firm quote for repairs or arrestor retrofits. Once the job’s done, we complete follow-up testing and safety checks to guarantee full PSSR compliance.

Why Professional Surge Modelling Matters

Transient surge waves move faster than the eye can follow. In many Victorian homes along the seafront, metallic pipes can resonate at certain frequencies and turn a small bump into a thunderous roar.

High-frequency pick-up identifies clip spacing errors

Surge maps reveal where air chambers must be replaced

Output reports guide the exact installation of large-scale arrestors

When DIY methods fail, this level of analysis pinpoints hidden risks and prevents costly damage down the line.

Safety Checks And Peace Of Mind

Quelling the noise is just part of the service. Every visit includes:

Pressure regulator verification up to 4 bar

Air chamber inspection and recharge

Surge relief valve tests at high points

All results come with your PSSR safety certificate, and our one-year guarantee covers both parts and workmanship.

Learn more about our rapid response in Eastbourne by checking our guide on Fast Plumbing Support When You Need It.

If your pipes still thump or your gauge swings unpredictably after a DIY attempt, call Harrlie Plumbing and Heating. We treat every job—big or small—with the same urgency we give to burst repairs.

“After Harrlie Plumbing fitted surge arrestors, my home has never been quieter.” — Local Eastbourne homeowner

Plus, you’ll enjoy these extras at no additional call-out fee:

Scheduled follow-up checks within 12 months

Detailed diagnostic report revealing surge origins

One-year warranty covering all parts and labour

Trust Harrlie Plumbing and Heating to silence your plumbing for good. Free quotes are available for all Eastbourne residents—book your appointment today.

Frequently Asked Questions

How long do water hammer arrestors really last, and when should you swap them out? In my experience, mechanical arrestors hold up for around 5–10 years before the seals start to give. With Eastbourne’s hard and soft water variations, I usually inspect them at about year seven to catch any early corrosion.

Key Insight: If you’re still hearing a thump or two after every valve close, the arrestor is probably on its last legs.

Can you recharge air chambers yourself? Absolutely. Simply turn off the mains, drain the pipes, and use a hand pump to refill the chambers. Always don some eye protection and double-check that the mains is fully isolated before you begin.

Choosing the right arrestor size can feel tricky. Here’s a quick guide:

Under-sink taps: 8 L/min

Washing machines: 15 L/min

If you need more detail, our sizing table in Section 3 will steer you straight.

Noticed loose or rusty clips along your pipework? Take a quick tally. If over 30% of them look worn out, it’s best to replace them all—this keeps the runs uniformly supported and quieter in the long run.

Further Advice

Still getting racket or spotted a leak? It’s time to call in a professional. An experienced engineer will carry out a pressure test, verify PSSR compliance, and fit commercial-grade arrestors where needed.

A simple annual inspection goes a long way in preventing unexpected thumps and drips.

For reliable local plumbing support, choose Harrlie Plumbing and Heating at https://www.harrlieplumbing.co.uk

Comments