What is a pressurised heating system? A clear guide

- Luke Yeates

- Nov 30, 2025

- 13 min read

If you've ever wondered what makes a modern central heating system tick, chances are you're thinking of a pressurised system. It's a sealed circuit, filled with a specific amount of water and brought up to pressure to work efficiently. Gone are the days of the old gravity-fed tanks taking up space in the loft; today's pressurised systems are a closed loop, delivering consistent, powerful heat and hot water right from your boiler.

What Is a Pressurised Heating System?

Think of your central heating like a car tyre. For it to perform correctly, it needs to be inflated to the right pressure. A pressurised heating system works on that same basic idea. It's a completely sealed network of pipes and radiators filled with water and then pressurised, which is a massive upgrade on traditional systems that relied on a bulky water tank in the loft.

This modern approach is now the standard for new installations and upgrades in countless Eastbourne homes, from Victorian terraces in Old Town to new builds down at Sovereign Harbour. The biggest win? It gets rid of the need for gravity and those loft tanks, freeing up valuable space and removing the nagging worry of leaks from overflowing tanks.

This quick table breaks down what a modern sealed system really means for your home.

Key Features of a Pressurised Heating System

Feature | What It Means for Your Home |

|---|---|

Sealed System | No open tank in the loft, reducing the risk of leaks and contamination. |

Mains Pressure | Delivers strong, consistent water pressure to your taps and showers. |

Compact Components | Frees up loft space and often requires less pipework. |

High Efficiency | Heats up quickly and operates more efficiently than older systems. |

Expansion Vessel | Safely accommodates water expansion as it heats up within the sealed loop. |

In short, these systems are designed to be neater, more powerful, and more reliable than their predecessors.

The Two Main Types of Pressurised Systems

When you hear people talking about pressurised heating, it usually boils down to two main setups. Knowing the difference will help you figure out what's best for your home's needs.

Combi Boilers: These are the compact, all-in-one units that give you both central heating and instant hot water straight from the mains. They're a fantastic fit for smaller to medium-sized homes with one or two bathrooms, offering great efficiency without taking up much room.

System Boilers: These boilers team up with a separate, pressurised hot water cylinder (often called an unvented cylinder). This setup is the go-to for larger properties with multiple bathrooms, as it can store and deliver a huge volume of high-pressure hot water to several taps at once.

As Eastbourne's local heating specialists, we at Harrlie Plumbing and Heating often find the choice between a combi and a system boiler comes down to your family's hot water habits and the size of your house. A family of four in a Meads property, for example, would almost certainly get more value from a system boiler to keep up with high demand.

At the end of the day, both boiler types run on the same core principle of a sealed, pressurised loop. This is what gives you better water pressure, gets your radiators warm faster, and provides a much more compact and efficient heating solution for your home.

How Your Pressurised System Delivers Heat

Think of your heating system as a continuous, sealed loop of water that starts its journey from your mains supply. This closed circuit is the secret behind the consistent, reliable warmth a pressurised system delivers throughout your home. The process itself is straightforward but incredibly effective.

Water from the mains enters your boiler, where it’s heated to the temperature you’ve set on your thermostat. A powerful internal pump then gets to work, pushing this hot water through the sealed network of pipes and circulating it to every radiator. Because the system is sealed and under pressure, the water moves much more quickly and efficiently, meaning your rooms heat up far faster than they would with an old, gravity-fed system.

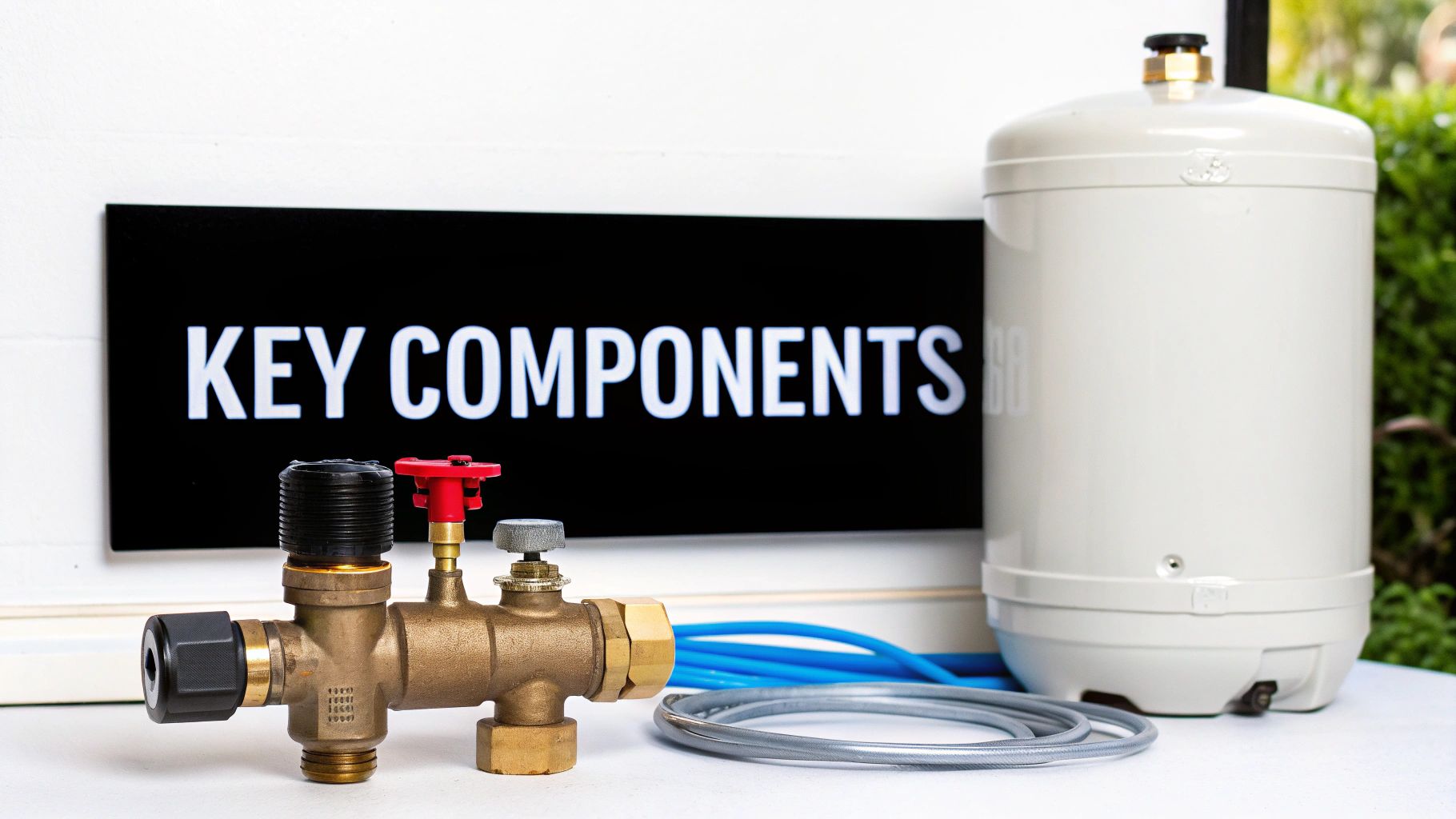

Key Components Working in Harmony

Several key components work together to manage this process safely. You can think of them as the skilled crew running your home’s heating engine. While the boiler is the heart of the operation, other parts are just as vital for keeping everything running smoothly.

A typical three-bedroom home in Willingdon, for example, sees a huge benefit from this kind of setup. The consistent pressure means powerful showers and radiators that heat up evenly from top to bottom, with none of those annoying cold spots. It's a noticeable upgrade in day-to-day comfort.

The real magic of a pressurised heating system lies in how it maintains stability. It’s a self-contained environment designed for one purpose: moving heat as efficiently as possible. This is why keeping an eye on the pressure gauge is so important—it’s your system's health dashboard.

Here are the crucial parts that make it all happen:

The Expansion Vessel: This is essentially the system's lung. As water heats up, it expands. The expansion vessel contains a diaphragm that absorbs this extra volume, preventing the system pressure from climbing to dangerous levels.

The Pressure Relief Valve (PRV): This is your most important safety net. If the pressure ever exceeds a safe limit (usually around 3 bar), this valve automatically opens to release water and bring the pressure back down to a safe level.

The Pressure Gauge: This is the little dial on the front of your boiler that shows you the system's current water pressure. For most systems, the needle should be sitting comfortably in the green zone, typically between 1 and 1.5 bar when the heating is cold.

This diagram shows the two main types of boilers that operate within this sealed loop.

Whether you have a combi boiler for instant hot water or a system boiler with a hot water cylinder, both rely on this same pressurised, sealed-loop principle to heat your home. At Harrlie Plumbing and Heating, we can advise on the best setup for your Eastbourne property.

Exploring the Core System Components

To really get your head around a pressurised heating system, it helps to know the key players working behind the scenes. Think of it like a team – each part has a specific job, and when they all work together, your home stays warm and comfortable. Getting familiar with them also helps you spot small issues before they snowball into big problems.

At the very heart of it all is the boiler. This is the engine room where the water is heated before it’s sent circulating through your radiators and out of your taps. Whether it’s a combi or a system boiler, its main role is generating the heat that keeps your Eastbourne home feeling cosy. It's also worth noting how well these setups can integrate with newer technologies like modern heat pump systems, offering even more efficient heating.

The System’s Lungs and Safety Net

Next up is the expansion vessel, which you can think of as the system’s lungs. When water heats up, it expands. It’s simple physics, but it can cause real problems in a sealed system. A 50-gallon cylinder, for example, can see its water volume grow by nearly half a gallon when heated. The expansion vessel is a small tank with a flexible diaphragm inside that safely absorbs this extra volume, stopping the pressure from climbing to dangerous levels.

That brings us to the system’s crucial safety net: the Pressure Relief Valve (PRV). This small but essential component is designed to automatically open and release water if the pressure ever gets too high, usually around 3 bar. It’s a vital failsafe that protects the boiler, pipework, and radiators from the serious damage that over-pressurisation can cause.

Finally, we have the filling loop. This is simply a small, flexible hose with a valve that connects your heating system to the mains water supply, allowing you to top up the water if the pressure drops. If you ever glance at your pressure gauge and see it’s fallen below the recommended 1 bar, the filling loop is what you’ll use to carefully bring it back up to scratch. To learn more about different boiler types, our guide on what is a combi boiler system goes into much more detail.

For coastal properties here in Eastbourne, from Langney Point to the cliffs at Beachy Head, the salty sea air can accelerate corrosion on external pipework. That’s why a professional installation from a team like Harrlie Plumbing and Heating is so important. We ensure every component, especially vulnerable parts like the filling loop and external pipes, is correctly fitted, secured, and protected to guarantee system integrity and longevity against the elements.

Pressurised Systems vs Traditional Open-Vented Systems

Choosing a heating system often feels like a contest between modern efficiency and old-school design. This is the classic matchup: the sleek, powerful pressurised system versus the traditional, gravity-reliant open-vented system. The differences are huge, affecting everything from your morning shower to how much storage space you have in your home.

A pressurised system is a completely sealed circuit, fed directly from your mains water supply. This setup gives you strong, consistent water pressure at every tap. On the other hand, a traditional open-vented system—often called a gravity-fed system—uses a big cold water tank in the loft to feed your taps and heating. It literally relies on gravity, which is why the water flow can often feel a bit lacklustre.

Let's break down the factors that really matter to homeowners.

Water Pressure and Performance

The most obvious difference you'll feel is the water pressure. Because pressurised systems are hooked up directly to the mains, they deliver a much more powerful and invigorating flow to your showers and taps. An open-vented system’s pressure is limited by how high the loft tank is above the tap. The higher the tank, the better the pressure, but it almost never comes close to what you get from the mains.

For anyone living in Eastbourne, especially in multi-storey properties or homes with a couple of bathrooms, this difference is night and day. A powerful shower is a daily luxury, and it's something a pressurised system delivers effortlessly.

Energy Efficiency and Running Costs

Modern pressurised systems, especially when paired with a combi boiler, are generally far more energy-efficient. They either heat water on demand or store it in a super-insulated cylinder, which minimises heat loss. Open-vented systems often have older, less efficient boilers and can lose a surprising amount of heat from that big water tank in the loft, particularly if it isn't properly insulated.

Upgrading from an old open-vented system to a modern pressurised one can lead to noticeable savings on your energy bills. It’s an investment in both your home's comfort and its long-term running costs.

Space and Installation Simplicity

Here’s where pressurised systems have a clear advantage. By getting rid of the need for a cold water tank in the loft, they free up a massive amount of valuable space. If you’re renovating a Victorian terrace in Eastbourne's Old Town, this is a game-changer. Suddenly, that loft conversion for a new bedroom or home office becomes a real possibility.

We’ve seen this firsthand at Harrlie Plumbing and Heating, where we have managed many such upgrades for local residents, turning dusty lofts into functional living areas. The installation itself is also a lot neater, with less pipework needed compared to the sprawling network you often find with a gravity-fed setup. To get a better handle on the older models, you can explore our guide on what is a gravity-fed system.

Comparing Pressurised and Open-Vented Heating Systems

To make it even clearer, here’s a side-by-side look at how these two systems stack up against each other. This table cuts through the jargon and shows you the key differences at a glance.

Feature | Pressurised System (Sealed) | Open-Vented System (Gravity-Fed) |

|---|---|---|

Water Pressure | High and consistent, direct from the mains. | Low to moderate, dependent on the height of the loft tank. |

Space Required | No loft tanks needed, freeing up valuable space. | Requires a large cold water storage tank in the loft. |

Energy Efficiency | Generally higher, with modern boilers and insulated tanks. | Often lower due to older boilers and heat loss from the tank. |

Hot Water Supply | On-demand (combi) or stored in a highly efficient cylinder. | Stored in a hot water cylinder, fed from the loft tank. |

Installation | Neater and often simpler, with less complex pipework. | More extensive pipework connecting the boiler and tanks. |

System Complexity | Sealed and requires an expansion vessel to manage pressure. | Simpler design, relies on an open vent for expansion. |

Best For | Modern homes, renovations, and properties with multiple bathrooms. | Older properties, or where mains water pressure is very low. |

While open-vented systems have reliably served UK homes for decades, the benefits of a modern pressurised system—superior water pressure, better efficiency, and more usable space—make it the clear winner for most homeowners today. It's simply a better fit for modern life.

Solving Common Problems and Maintenance Tips

Even the most dependable pressurised heating system can have an off day. The good news? Many common hiccups are easy to spot and, in some cases, surprisingly simple to sort out yourself. Knowing what to look for helps you keep your system in top shape and tells you when it’s time to call in the professionals.

One of the most frequent issues homeowners run into is a loss of pressure. You might glance at your boiler’s pressure gauge and notice the needle has dipped out of the green zone, which is usually anything below 1 bar. This can happen right after you’ve bled your radiators, but if you find it dropping time and time again, it could be flagging up a bigger problem.

Another classic complaint is hearing strange gurgling or banging noises coming from your radiators or pipes. This is almost always down to trapped air in the system. These air pockets get in the way of the water flowing smoothly, leading to patchy heating and those annoying sounds.

Simple DIY Fixes You Can Try

Before you reach for the phone, a few quick checks can often get your heating back on track. These are tasks that most homeowners can comfortably handle.

The number one DIY job is bleeding your radiators. If a radiator is cold at the top but warm at the bottom, that’s the textbook sign of trapped air. Grab a radiator key, gently release the air until water starts to spit out, and you’ll allow hot water to fill the radiator properly again. Just remember to check the system pressure afterwards, as you’ll probably need to top it up a little using the filling loop.

When to Call the ProfessionalsA key indicator that you need expert help is having to repressurise your system frequently. If you're topping it up every month, this strongly suggests a leak somewhere in the system. Ignoring this can lead to water damage and costly repairs, so it's best to have a Gas Safe engineer from a trusted local company like Harrlie Plumbing and Heating diagnose and fix the underlying issue promptly.

Your Annual Maintenance Checklist

Being proactive is the best defence against heating headaches. A simple annual routine will stop many common problems from ever starting.

Here’s a quick checklist to keep you on track:

Check the Pressure: Take a quick look at your boiler's pressure gauge once a month. It should be sitting steady between 1 and 1.5 bar when the heating is off and the system is cold.

Bleed Radiators: At the start of autumn, just before you fire up the heating for the season, bleed all your radiators. This gets rid of any air that’s built up over the summer months.

Visual Inspection: Have a walk around and look at your radiators and any visible pipework. Check for tell-tale signs of leaks or corrosion, paying close attention to the valves and joints. Catching a small drip early can save a world of trouble.

Schedule a Professional Service: An annual boiler service by a certified engineer isn't just a good idea—it's essential. They’ll check all the safety components, clean out the internal parts, and make sure everything is running as efficiently as it should be.

To keep your entire hot water circuit in good working order, checking out some essential hot water maintenance tips can also offer some great advice. If you're still puzzled by pressure problems, our guide on what causes a boiler to lose pressure dives deeper into the causes and solutions.

Got Questions About Pressurised Heating? We've Got Answers

Even after getting your head around the basics, you might still have a few things you’re wondering about. Here are some clear, straightforward answers to the questions we hear most often from homeowners around Eastbourne, helping you feel completely confident in your heating system.

Are Pressurised Heating Systems Safe to Have in My Home?

Yes, they are exceptionally safe—as long as they’re installed and looked after properly. Every system is built with essential safety features, with the most important one being the Pressure Relief Valve (PRV). This clever component is designed to automatically release water if the pressure ever creeps above a safe limit, which prevents any risk of damage.

To ensure everything is working as it should, it’s a legal requirement that any installation or servicing is done by a certified Gas Safe engineer. At Harrlie Plumbing and Heating, our annual service checks across Eastbourne always include a thorough inspection of all safety devices, so you can have complete peace of mind.

How Often Should I Need to Top Up the System Pressure?

Honestly, not very often. A healthy, well-maintained pressurised system should hold its pressure for a long time. You might only need to give it a little top-up once a year, usually after you’ve bled the radiators to get rid of any trapped air.

If you find yourself having to top up the pressure every few weeks or months, that’s a big clue there's a leak somewhere in the system. Even if it's just a tiny, slow drip you can't see, it's best to get a professional to investigate. Catching it early can prevent water damage and keep your system running efficiently.

Can I Install a Pressurised System in an Older House?

Absolutely! Upgrading an older property in areas like Upperton or Roselands to a modern pressurised system is a brilliant way to boost energy efficiency and improve your daily comfort. Many period homes right here in Eastbourne have made this exact switch with fantastic results.

There is one important step, though. It’s vital to have a professional assess the condition of your existing radiators and pipework first. The higher pressure of a sealed system can put a strain on older components that might be a bit fragile. A proper survey from our team at Harrlie Plumbing and Heating will tell you if any parts of the old system need updating to ensure your new installation is reliable, leak-free, and built to last.

What Is an Unvented Cylinder and Do I Need One?

Think of an unvented cylinder as a pressurised hot water storage tank that’s fed directly from your cold water mains. You would only need one of these if you opt for a system boiler instead of a combi.

This setup is the perfect solution for larger Eastbourne homes, especially those with multiple bathrooms. It stores a large volume of hot water and can deliver it at high pressure to several taps at once. That means no more weak showers just because someone is washing up downstairs! For smaller homes with less demand for hot water, a combi boiler (which heats water on the fly) is usually the more practical and space-saving choice.

If you have more questions or just need some expert advice on your heating system, Harrlie Plumbing and Heating is here to help. From annual servicing to full system upgrades, we provide reliable, professional services across Eastbourne. Contact us today for a free, no-obligation quote.

Comments